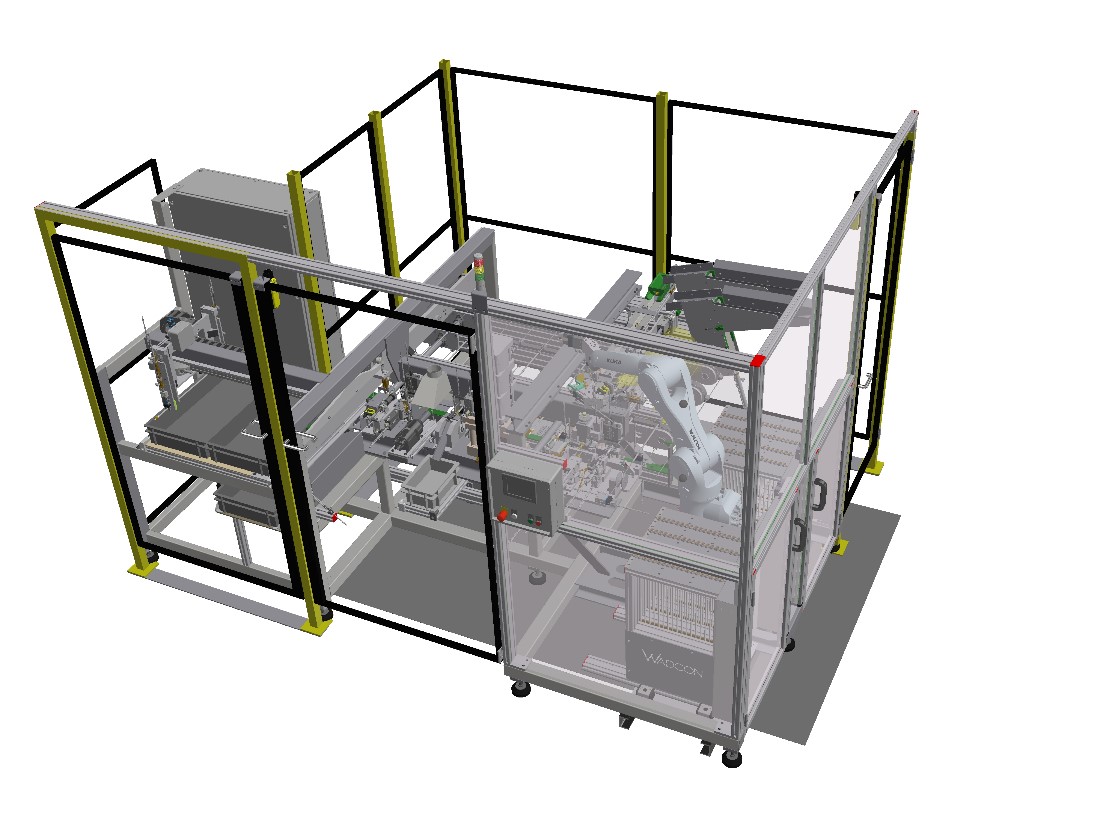

The hose manufacturing machine assembles a dependable joint at the end of the hose which will be resistant/stay in place in a range of cold to boiling water.

An industrial robot is used to handle the hoses onto a pin rack, positioning them for automated fitting and fixing with a crimping solution. The internal material is then cut and trumped to exacting standards. After the testing and validation steps the hoses are stacked in trays for assembly in the main units.