Een groep van hoogwaardige bedrijven in aandrijf-, hijs- en heftechniek.

Wadcon on Robot Integration

Making things in Europe is essential to keep our industrial base healthy. Automation is the only way to compete with low labour cost countries. Integrating robots, cobots and AGV’s is a fast, flexible and efficient way of automating production.

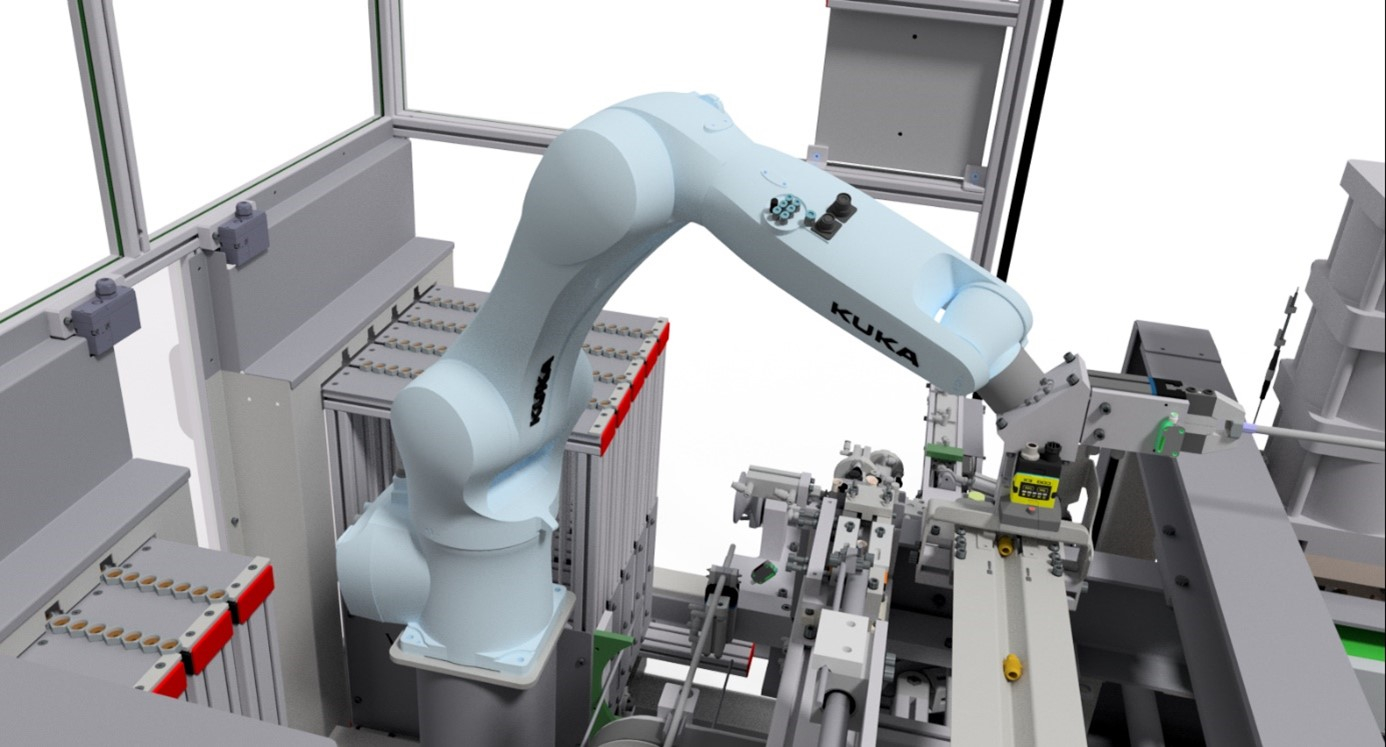

Wadcon works with Kuka robots and Doosan Cobots

Wadcon has long experience with automation processes based on custom engineering. In the present day the cost of robots and cobots and the intelligence and tools available has developed such that we often use robots and cobots to implement automation rather than custom engineered solutions. We will still custom design the tooling for the purpose required as we find that it is the Tooling that makes the Robot, to paraphrase the saying that the ‘shoes make the man’. This allows for fast and efficient solutions for many process- and material handling requirements. Wadcon will further develop and market the tooling under the brand name Toolit.

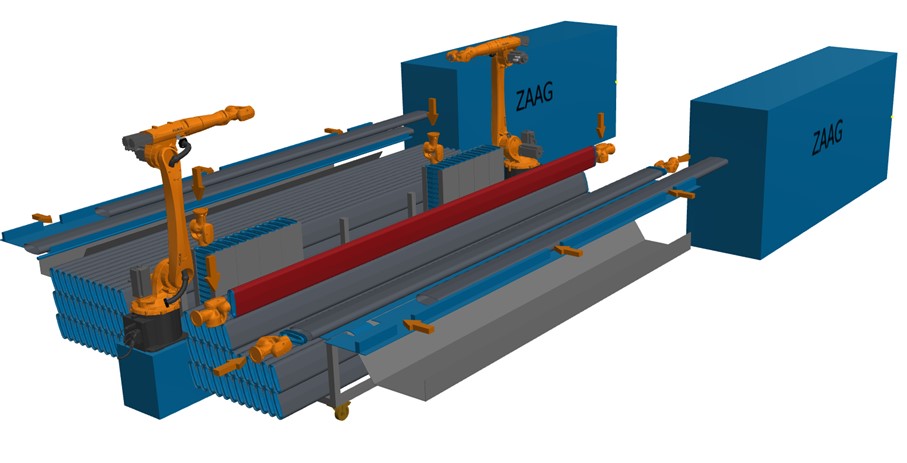

for an extruder including fitting of plugs for transport.: This packing system is part of a modular solution for all the packing lines. The same combination of tooling, robots and packing positions can fulfil all the packing requirements in the plant. This eases maintenance and increases reliability. It is also cheaper in both Capex and running cost.. Wadcon developed the tooling options, the tube landers and the integral system.

Automated dosage, icing, shaking , straining and pouring of any cocktail you may wish to program.

Your barman now has all the time to be a host to your customers, while at the same time fast and constant quality production ensures you need less staff on the bar. It also means tracking the quantities, helping your stock keeping and tracking bar revenue.It will even calculate a new cocktail and produce an advisory price when required…. And look great at the same time!

Wadcon developed the concept, software, stand-alone system and tooling for the Cobar

This palletiser has all the advantages of a cobot application: Easy reprogramming and user friendly application. As the cobot can usually work directly at the conveyor without extra fencing around it so that it can be moved easily from work station to work station. The sensors built into the unit sense the pallet location and also sense the approach of people or vehicles, slowing down the cobot until the area is clear and safe. Wadcon has the Toolit program of vacuum and light weight gripper tooling available to use as end effectors.

Should you have any questions or enquiries on how Wadcon could improve your industrial processes, please don’t hesitate to contact us and we shall revert fast.